|

An

American engine for the Vickers Gunbus in 1915

At

the outset of World War 1 the only aircraft designed for fighting in

the air was the Vickers Gunbus (later FB5). Initial orders for

the aircraft had come from the Navy but much of the production was

handed over (transferred) to the Army for the RFC.

In

the search for improved performance an engine designed by American

aviation pioneer and engine designer Mr John W Smith, the

Smith Static Motor, was trialled for the Vickers aircraft. Mr

Smith moved to England in 1915 and set up the British Static Motor Company

in Birmingham in partnership with Mr Charles Schofield. He

brought with him from Chicago an experienced engine mechanic Mr

Ralph Watson.

© J Soderberg

© J Soderberg

Smith

Static Motor (on test stand)

During

1915 the engine was demonstrated to the Admiralty and the War Office

and was installed that summer on two Vickers FB5 aircraft (serial

no.s 1534 & 1535) for the Admiralty, the first of which was

delivered to RNAS Eastchurch (Isle of Sheppey) on 7 August 1915. The

Smith engine was relatively light and claimed to deliver 140 hp.

Watson

wrote to his wife on 8 August 1915 the day after No.1534s delivery:

"Just

arrived in Birmingham from London, it takes a little over 2 hours to

make the trip. I will be here for about a week I think unless they

have trouble with the motor down at the flying field. I was out to

the field [Joyce Green, Vickers test flight] yesterday

and saw them off for the other flying field belonging to the Navy [RNAS

Eastchurch]. And they want to play with it themselves for a

few days and make a few more tests. I was up the other day Friday it

was [30 July] with Mr. Barnwell the pilot [Vickers Chief

test pilot Harold Barnwell], he is one of the very best

there is over here so I am told and he knows how to fly all right. We

were only up at 1200 to 1500 feet, took a trip over a little Suburb

of London out there, and up and down over the Thames river and I felt

much safer in it than in an auto doing 60 mile per. hr. and we were

going better than 80 M.P.H."

©

J Soderberg ©

J Soderberg

Vickers

FB5 aircraft 1534

Clearly

more work was required to get the engine right. JW Smith wrote

to Watson (probably at RNAS Eastchurch) on 7 Dec 1915:

"I

sent along a valve unit, which consists of valve cage, exhaust and

intake valve so you could take out one of the old valves and put in

the new one.

The

old valves that are in the motor come from the States, and I thought

it would be well to keep one of these valves to show to anyone when I

wished to convince that after the motor had made 200 hours run the

valve was practically as good as new.

The

new Carburettor works perfectly on both high and low.

The

new sight feed [clear pipe for viewing the flow] works nicely

for any amount of oil that I want to use it on, and you had better

put in this new sight feed, and let it run a good bifuel stream to

the extent of 1 1/4 gal. to 1 1/2 gal. per hour which means a pretty

thick stream as the oil is heavy and moves slow.

I

gave the motor an hours run to-day to limber it up, and ground the

valves. If it has the punch to-morrow I will call up the Officials

for a test."

The

then RFC HQ Chief of Staff Lt Col. Brooke-Popham mentioned

the engine in a January 1916 report of his visit to Home

Establishment as follows:

The

Smith Radial engine was tested on Tuesday [18 Jan 1916]. It

ran for an hour giving 140 hp. and then broke a valve rocker. Its

weight is only 180 lbs. and if it can be got right it would seem that

it would be a very useful engine.

The

same report notes however the imminent arrival of a squadron of

FE2bs with 240 hp Rolls-Royce engines, another pusher aircraft that

effectively took over from the Vickers FB5 and 9, and saw out the war

as a night bomber.

Watson

writing to a friend at the Standard Steel Car Company in the US in

March 1916 commented on engines:

If

you are getting into this game you will find that it must be a motor

of the radial type and no doubt air cooled as that eliminates more

weight than anything else and pounds per HP will always be the

determining factor in aeroplane work. Besides the radial type lends

itself to plane construction on mounting. It takes one man about 4

days to dismount a Sunbeam motor from a fuselage. I have taken one of

Smith’s motors (off) in 20 minutes.

Flt

Cdr? W A Bristow writing to J W Smith in October 1916 from

the Admiralty Air Department was enthusiastic about the engine’s performance:

Working

out your figures after the test today I find the engine gave 131.3

BHP at 1,275 and the petrol consumption was .67 pts per BHP hour.

This

seems to be very good and the engine certainly ran better than ever.

It will be as well I think to lock the carburettor in the position we

ran it in today as I should like it to go into the air just as it was.

With

regard to request for suggestions as to improvements I am afraid it

is difficult to suggest anything really worth talking about. The

position of the carburettor might be changed &ldots;

But

as to the design and make of the engine there is nothing I can

suggest as an improvement. As you know I have flown with the engine

about a thousand miles and I certainly feel safer with it than almost

any other engine I have been up with.

What

I like about it is the ease of control and absence of vibration over

a wide range of speed and considering we have had to come down once

only and that not through any particular fault in the engine. It

speaks pretty well for it. Would it be possible to make a large

engine say 200/220 HP. You might think it over and let Commander

Briggs know.

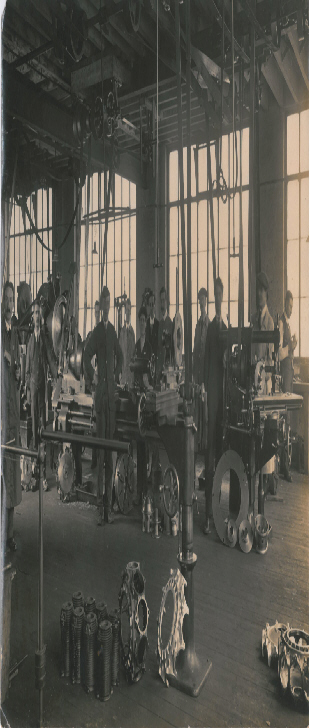

©

J Soderberg

Smith’s

workshop in Birmingham

J

W Smith sold his share of the business (UK patent rights) to Mr

Heenan of Heenan & Froude Ltd in early 1916 but stayed on

under contract in UK to help the business at the Admiralty’s

request. The Smith motor production was moved to Heenan & Froude

Ltd at Worcester (see www.miac.org.uk/heenan.htm

) in April 1916 and the manufacturing suffered a number quality

problems leading eventually to the engine’s rejection by the Air

Board. The company had an initial order for 250 engines.

There

had been plans to fit a 140 HP Smith Static Motor in a prototype

seaplane PV4 designed by the Admiralty’s Port Victoria

Marine Experimental Aircraft Depot in 1916. The engine was not

delivered so a Clerget was tried in June 1917 but this proved too

long in body (compared to the Smith) to rig the machine for

longitudinal control across the speed range. A prototype for another

Admiralty designed float plane the AD Naviplane No. 9095 was

built in 1916 by Supermarine initially with a 150 HP Smith Static,

but this proved underpowered and the engine was replaced by a Bentley

Rotary 1 in 1917 which also failed to deliver the required

performance. The design was abandoned. The Blackburn TB twin

engine seaplane had been another possible user of the Smith 140

HP engine but smaller engines had to be fitted and again it proved

under powered.

A

new company, Smith’s Static Motor Company, was

registered in November 1916, essentially holding the UK patent rights

for the Smith motor. Heenan with Schofield and others were

Directors of the new company. J W Smith had then returned to

the US because of his wife’s ill health (she was a survivor of

the sinking of the RMS Lusitania and continued to be in poor health).

Watson

continued to work for Smith’s Motors and went to France as part

of efforts to promote the engine to the French Air Service. By

October 1917 a 190 HP engine was available and being offered as a

test engine to the French. Watson had been asked by J W Smith to file

patents for the engines in France with a view to licensed production.

Watson reported that negotiations with the French were hampered by

the lack of clarity as to who was running the company in UK.

Schofield had visited Paris in November and fallen seriously ill and

proposals were not progressed. This seems to mark the end of the line

for the Smith’s engine.

The

British Ministry of Munitions had taken a decision in 1917 to

concentrate engine manufacturing efforts on six aero engines two of

which, the Clerget and Bentley Rotary 1 (BR1), were in the same

category as the Smith Static. It would seem that the Smith

company’s efforts were consequently directed toward the French market.

After

WW1 the French company Darracq which had built FB5s under licence

from Vickers acquired Heenan & Froude Ltd. The latter continued

in existence after the Darracq amalgamation with Sunbeam Talbot, as

STD, and was sold off as a going concern after STD’s bankruptcy

in 1935.

Sources:

R

O Watson private papers

National

Archives (UK) Air 1/992/204/5/1214 report by Brooke-Popham

Brooklands

Museum Trust Archives (delivery of aircraft No. 1534 to Eastchurch)

Photographs

copyright J Soderberg

Copyright

© 2013 www.airwar1.org.uk

|